JRZ for materials processing with ultrashort pulsed laser sources

The Josef Ressel Center for Materials Processing with Ultra-short Pulsed Laser Sources was successfully completed in 2018 and transferred to follow-up projects.

In Josef Ressel Centers, application-oriented research is conducted at a high level, with outstanding researchers cooperating with innovative companies. The Christian Doppler Research Association is internationally regarded as a best practice example for the promotion of this cooperation.

The Josef Ressel Center for Materials Processing with Ultra-short Pulsed Laser Sources was a joint initiative with Spectra-Physics Rankweil. The focus was on research-related collaboration.

Josef Ressel Centers are jointly funded by the Federal Ministry of Science, Research and Business (BMWFW) and the participating companies.

Research Areas

Research is being conducted on a fundamental understanding of laser-matter interaction in ultrashort laser pulses. The focus is on materials that are difficult to process with conventional laser sources and on materials that are considered promising for the development of microsystems.

Important here is the control and analysis of the process parameters. The center has extensive analytics for this purpose, from sample preparation to electron microscopy.

Research findings are applied to some special fields: Processing of dielectric materials and polymeric materials, and selective ablation of microtechnology layer systems.

Possible application areas for the research results are many: Biochips, sensors, microsystems, microfluidics (behavior of liquids and gases in smallest space).

Surface Functionalization

One of the main focuses of research at the Josef Ressel Center has been on surface functionalization. Functionalization is understood here as the control of surface wetting behavior by means of laser structuring

The femtosecond laser is an ideal tool to produce almost any surface topographies by a fast direct writing process. In addition, the femtosecond laser has the ability to pattern a wide variety of materials with high precision and with minimal thermal stress. As a result of this work, a fabrication process has been developed to produce surfaces with high wetting contrast, among other things. This process has been patented by project partner Spectra-Physics and marketed as ClearSurface.

Clear surfaceTM

The manufacturing process of a functional surface based on ClearSurfaceTM takes place in three steps. In the first, a hydrophilic (water-attracting) substrate, such as glass, is structured with a laser. The goal is to produce a so-called hierarchical surface structure, in which geometries in the micrometer range overlap with smaller structures in the nanometer range.

After this first structuring step, the surface behaves superhydrophilic (strongly water-attracting). Subsequent coating with a Teflon-like polymer as a second step makes the same surface superhydrophobic with a wetting behavior similar to lotus bloom (lotus effect).

In order to produce structures with high wetting contrast, a final structuring step follows in which the polymer layer is selectively ablated again with the femtosecond laser. Due to the direct-writing laser process, this can be implemented with any geometries. The high wetting contrasts are demonstrated in the figure. The Spectra-Physics logo made of water is shown. The substrate is flat, and the water is literally piled up just by the very large differences in the wettability of the surface.

Bionics

An example of how ClearSurfaceTM is used in the field of bionics was demonstrated in a master's thesis. In this, the surface of a "fog-drinking" desert beetle was recreated using laser structuring. Tiny hills on the wings of this beetle exhibit a smooth, water-attracting surface.

The valleys in between, on the other hand, are rough and coated with a wax-like substance so that they repel moisture. As soon as the water droplets hanging from the elevations reach a certain size, they break away and roll down through the channels to the beetle's mouth. This behavior from nature could be replicated with ClearSurfaceTM on a glass surface. Measurements show a significant increase in water collection rate compared to an unprocessed sample.

Publication related:

- E. Kostal, S. Stroj, S. Kasemann, V. Matylitskaya and M. Domke: Fabrication of Biomimetic Fog-Collecting Superhydrophilic-Superhydrophobic Surface Micropatterns Using Femtosecond Lasers, Langmuir 34(9):2933-2941 (2018), doi: 10.1021/acs.langmuir.7b03699.

Manufacture of piezo-actuators from PMN-PT

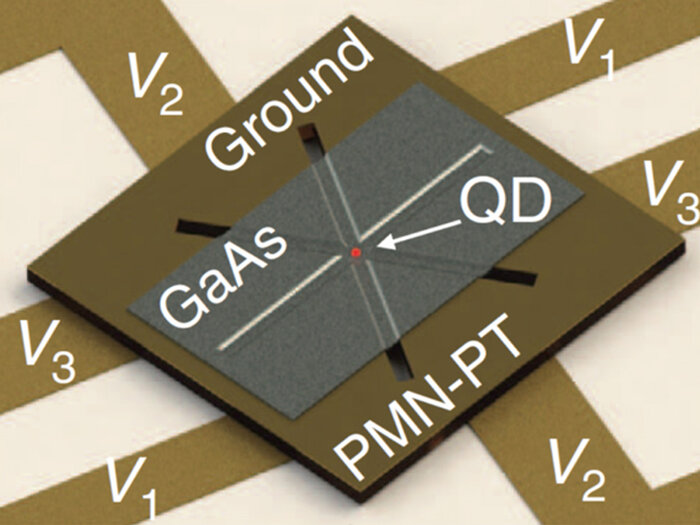

Due to its low thermal stress during processing, the femtosecond laser is the ideal tool for processing brittle and temperature-sensitive materials. These include lead magnesium niobate-lead titanate (PMN-PT), for example. This piezoelectric crystal exhibits unusually high dielectric and piezoelectric properties.

At the Institute of Solid State Physics at the University of Linz, a piezo-actuator has been designed which, by applying a defined voltage, allows the energy of entangled photons emitted by QDs to be tuned without affecting the degree of entanglement of the photon pairs.

This PMN-PT-based actuator has a star-shaped geometry that is very difficult to fabricate using conventional methods. For this reason, an fs laser cutting process was developed at the Ressel Center to manufacture the actuator. The piezoelectric properties of the crystal must not be impaired in the process. Furthermore, certain requirements regarding accuracy and edge quality must be met.

This prevents crack propagation when voltage is applied or enables the manufacture of components with minimal gaps between the actuator arms.

Publication on this:

- Martín-Sánchez J., Trotta R., Piredda G., Schimpf C., Trevisi G. and Seravalli L. , Frigeri P. , Stroj S. , Lettner T. , Reindl M. , Wildmann J. S. , Edlinger J. , Rastelli A. "Reversible Control of In-Plane Elastic Stress Tensor in Nanomembranes," Advanced Optical Materials, Doi: 10.1002/adom.201500779

- Trotta R., Martín-Sánchez J., Wildmann J. S., Piredda G., Reindl M., Schimpf C., Zallo E., Stroj S., Edlinger J. and Rastelli A. "Wavelength-tunable sources of entangled photons interfaced with atomic vapours" Nat. Comm. ,15, 10375 (2016). Doi:10.1038/ncomms10375

- G. Piredda, S. Stroj, D. Ziss, J. Stangl, R. Trotta, J. Martin-Sanchez, and A. Rastelli "Micromachining of PMN-PT crystals with ultrashort laser pulses" Arxiv:1811.12287 (2018)

Past Publications

| E. Kostal, S. Stroj, S. Kasemann, V. Matylitsky, and M. Domke, "Fabrication of Biomimetic Fog-Collecting Superhydrophilic-Superhydrophobic Surface Micropatterns Using Femtosecond Lasers," Langmuir, 2018, 34 (9), pp 2933-2941. | |

| J. Martin-Sanchez, R. Trotta, A. Mariscal, R. Serna, G. Piredda, S. Stroj, J. Edlinger, C. Schimpf, and more, "Strain-tuning of the optical properties of semiconductor nanomaterials by integration onto piezoelectric actuators," Semiconductor Science and Technology, 2018, 33(1), 013001 (39 pp.), DOI: 10.1088/1361-6641/aa9b53. | |

| M. Spellauge; F. Loghin; J. Sotrop; M. Domke; M. Bobinger; A. Abdellah; M. Becherer; P. Lugli; H. P. Huber: "Ultra-short-pulse laser ablation and modification of fully sprayed single walled carbon nanotube networks". Carbon, 138, 234-242. 2018. DOI: 10.1016/j.carbon.2018.05.074. | |

| R. Moser; M. Domke; J. Winter; H. P. Huber; G. Marowsky: "Single pulse femtosecond laser ablation of silicon - a comparison between experimental and simulated two-dimensional ablation profiles". Advanced Optical Technologies. 2018. DOI: 10.1515/aot-2018-0013. | |

| M. Domke; S. Wick; M. Laible; S. Rapp; H. P. Huber; R. Sroka: "Ultrafast dynamics of hard tissue ablation using femtosecond-lasers". Journal of biophotonics, e201700373. 2018. DOI: 10.1002/jbio.201700373. | |

| S. Ströbl, M. Domke, Ch. Vonach, J. Gratt, T. Trebst, R. Sroka: Ultrafast-laser fabrication of optical fiber diffusers for medical applications, LPM 2018, 25-28 June 2018, Edinburgh, Great Britain. |

| J. Voyer, F. Ausserer, S. Klien, A. Ristow, I. Velkavrh, A. Diem, J. Zehetner, S. Stroj, S. Heidegger, C. Bertschler, and J. Edlinger, "Sub-Micro Laser Modifications of Tribological Surfaces," Materials Performance & Characterization - Special Issue on Surface Texturing; DOI: 10.1520/MPC20160015. | |

| M. Domke; B. Egle; S. Stroj; M. Bodea; E. Schwarz; G. Fasching: "Ultrafast-laser dicing of thin silicon wafers". Applied Physics A, 123, 12, 553. 2017. DOI: 10.1007/s00339-017-1374-7. | |

| S. Stroj; S. Kasemann; M. Domke; G. Piredda; J. Zehetner; V. Matylitskaya: "Transparent superhydrophobic surfaces with high adhesion generated by the combination of femtosecond laser structuring and wet oxidation". Applied Surface Science, 420, 550-557. 2017. DOI: 10.1016/j.apsusc.2017.05.045. | |

| Method for selectively enhancing wetting characteristics for substrate, involves applying substrate coating to substrate and feature, and selectively ablating portion of substrate coating from substrate to expose feature formed on substrate, Patent Number(s): WO2017142958-A1, Inventor(s): M. Domke, E. Kostal, S. Stroj, S. Kasemann, F. Hendricks, V. Matylitsky, Patent Assignee Name(s) and Code(s): NEWPORT CORP (NEWP-Non-standard) |

| M. Bandić, G. Verbanac, M. B. Moldwin, V. Pierrard, G. Piredda, "MLT dependence in the relationship between plasmapause, solar wind, and geomagnetic activity based on CRRES: 1990-1991," Journal of Geophysical Research - Space Physics, 121, 4397 (2016), Doi: 10.1002/2015JA022278 | |

| Matthias Domke, Elisabeth Kostal, Sandra Stroj, Stephan Kasemann, Volha Matylitskaya, Collecting water like a fog-drinking beetle: Fabrication of biomimetic surfaces with fs-lasers, Workshop Generation of bionic surfaces by laser structuring, Nuremberg, Germany, November 16, 2016. (Presentation only) | |

| Matthias Domke, Bernadette Egle, Giovanni Piredda, Sandra Stroj, Gernot Fasching, Marius Bodea, Elisabeth Schwarz. Ultrashort pulse laser dicing of thin Si wafers. Journal of Micromechanics and Microengineering. 26(11), 115004 (2016), DOI: 10.1088/0960-1317/26/11/115004. | |

| Matthias Domke, Benjamin Bernard, Victor Matylitsky, Ultrashort pulse laser dicing of thin silicon wafers: influence of pulse duration and burst mode on cutting speed and quality, 42nd Micro and Nano Engineering (MNE 2016), 19-23 September, Vienna, 2016. (Presentation only). | |

| Stephen Ho, Matthias Domke, David Roper, Heinz P. Huber, Peter R. Herman, Femtosecond Laser Quantized Structuring in thin SiOx Film, CLEO: Science and Innovations 2016, San Jose, California United States, June 5-10, 2016, DOI: 10.1364/CLEO_SI.2016.STh3Q.4. | |

| Martín-Sánchez J. , Trotta R. , Piredda G. , Schimpf C. , Trevisi G. and Seravalli L. , Frigeri P. , Stroj S. , Lettner T. , Reindl M. , Wildmann J. S. , Edlinger J. , Rastelli A. "Reversible Control of In-Plane Elastic Stress Tensor in Nanomembranes," Advanced Optical Materials, Doi: 10.1002/adom.201500779 | |

| Trotta R., Martín-Sánchez J., Wildmann J. S., Piredda G., Reindl M., Schimpf C., Zallo E., Stroj S., Edlinger J. and Rastelli A. "Wavelength-tunable sources of entangled photons interfaced with atomic vapours" Nat. Comm. ,15, 10375 (2016). Doi:10.1038/ncomms10375 | |

| Matthias Domke, Bernadette Egle, Giovanni Piredda, Gernot Fasching, Marius Bodea, Elisabeth Schwarz, Investigation of the breaking strength of ultrashort pulse laser diced thin Si wafers, Laser Applications in Microelectronic and Optoelectronic Manufacturing (LAMOM) XXI, San Francisco, California, United States, 13 - 18 February 2016 (Presentation only) | |

| Matthias Domke, Johannes Gratt, Ronald Sroka. Fabrication of homogeneously emitting optical fiber diffusors using fs-laser ablation. Proceedings of SPIE - The International Society for Optical Engineering. 97400O, 1-10 (2016), DOI: 10.1117/12.2212475. | |

| Matthias Domke, Giovanni Piredda, Johann Zehetner, Sandra Stroj. Minimizing the Surface Roughness for Silicon Ablation with Ultrashort Laser Pulses. Journal of Laser Micro/Nanoengineering. 11(1), 100-103 (2016), DOI: 10.2961/jlmn.2016.01.0019 |

| Domke, M. Transient physical mechanisms in laser ablation of thin metal films Dissertation: ISBN 978-3-87525-385-6 | ||

| Domke, M., Piredda, G., Zehetner, J., and Stroj, S., Minimizing the surface roughness for silicon ablation with ultrashort laser pulses Proc. LAMP 15-021, 1-4 (2015). | ||

| Zehetner, J., Domke, M., Piredda, G., Kraus, S., Lucki, M., Vanko, G., Dzuba, J., Ryger, I., Lalinsky, T., Benkler, M., Laser polarization condition affecting ablation quality of thin membranes for SiC or ceramic based GaN/ferroelectric thin film MEMS and pressure sensors Proc. LAMP 15-053, 1-6 (2015) | ||

| Piredda G., Rein A., Zehetner J. and Matylitsky V., Mechanical properties of ultrafast-laser cut poly(lactic acid) films, Proc. LIM, (2015). | ||

| Domke, M., Piredda, G., and Stroj, S., Calculating the optimal combination of pulse-to-pulse distance and fluence for scribing and patterning with ultrashort pulsed lasers Proc. LIM, 1-6 (2015). | ||

| Domke, M., Gavrilova, A., Rapp, S., Frentzen, M., Meister, J., and Huber, H. P., Time-resolved microscopy reveals the driving mechanism of particle formation during ultrashort pulse laser ablation of dentin-like ivory Journal of Biomedical Optics 20(7), 76005 (2015); doi:10.1117/1.JBO.20.7.076005 |

Domke, M., Felsl, D., Rapp, S., Sotrop, J., Huber, H. P., and Schmidt, M., Evidence of Pressure Waves in Confined LaseAblation J. Laser Micro Nanoeng. 10(2), 119-123 (2015); doi:10.2961/jlmn.2015.02.0002

.

| M. Domke: The state of matter of thin molybdenum films at the ablation threshold using ns- and ps-pulses, Laser Processing in Photovoltaics, 27 to 28 November 2014, Leipzig, Germany. | ||

| J. Zehetner, G. Vanko, P.Choleva, J.Dzuba, I.Ryger, T.Lalinsky: Using of laser ablation technique in the processing technology of GaN/SiC based MEMS for extreme conditions, ASDAM 2014, 20 to 22 October 2014, Smolenice Castle, Slovakia.DOI: 10.1109/ASDAM.2014.6998693 | ||

| B. Fäßler, G. Piredda and Johann Zehetner: SYSTEMATIC STUDY OF THE ROUGHNESS OF BIODEGRADABLE POLYMER SURFACES PROCESSED BY ULTRASHORT LASER PULSES,ICALEO 2014, 19 to 23 October 2014, San Diego, CA, USA.Show PDF: Paper | ||

| M. Domke, L. Nobile, S. Rapp, S. Eiselen, J. Sotrop, H. P. Huber, M. Schmidt, Understanding thin film laser ablation: the role of the effective penetration depth and the film thickness, 8th International Conference on Photonic Technologies LANE 2014,08 to 11 September, 2014, Physics Procedia 56 ( 2014 ), 1007 - 1014. DOI: 10.1016/j.phpro.2014.08.012 | ||

| M. Domke, S. Wick, H. Huber, M. Wahler, J. Edlinger, C. Homann, J. Kutnesova, R. Sroka, Investigations of the damage mechanisms during ultra short pulse laser ablation of dental tissue, International Conference on Laser Applications in Life Sciences, 29 June to 2 July 2014, Ulm, Germany.Show Abstract: SPIE | ||

| M. Domke, D. Felsl, S. Rapp, J. Sotrop, H. P. Huber, M. Schmidt, The role of shockwaves in confined laser ablation, Proceedings of LPM2014 - the 15th International Symposium on Laser Precision Microfabrication, Vilnius, Lithuania, 2014. show PDF:paper | ||

| T. Pacher, A. Prinz, S. Partel, V. V. Matylitsky, S. Stroj, Microstructuring of resist double layers by a femtosecond laser ablation and UV lithography hybrid process, Photonics West 2014, 2 to 6 February 2014, San Francisco, Paper: 8968-24. DOI: 10.1117/12.2037683 | ||

| T. Pacher, A. Prinz, S. Partel, V. V. Matylitsky, S. Stroj, Selective structuring of thick SU-8 layers on fused silica by femtosecond laser ablation for medical applications, Photonics West 2014, 2 to 6 February 2014, San Francisco, Paper: 8976-3. |