hbCC - Hydrate Based Carbon Capture

Despite the greenhouse gas emission reduction targets set in the Paris Climate Agreement, many countries are missing them at regular intervals. Replacing high-emitting technologies with more efficient, cleaner and sustainable solutions is simply expensive and very time-consuming. With the help of industrial CO2 capture (carbon capture) from high-emitting point sources, e.g. gas-fired power plants, existing and hard-to-replace infrastructure can be made lower-emitting, thus gaining time for their replacement.

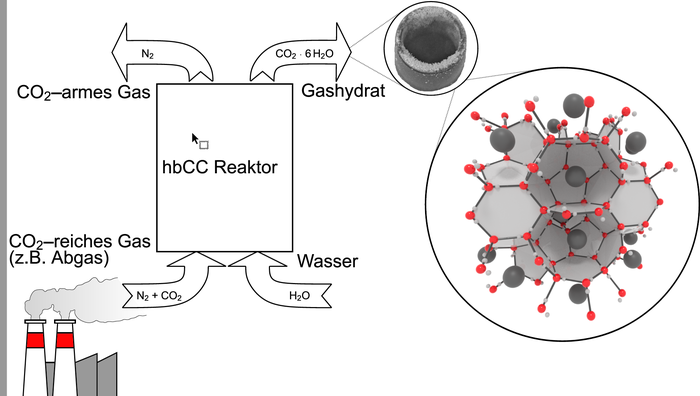

In the exploratory project Hydrate-Based Carbon Capture, or "hbCC" for short, the Vorarlberg University of Applied Sciences (FHV - Vorarlberg University of Applied Sciences) is researching and developing a new process for CO2 capture that is particularly environmentally friendly due to the exclusive use of water as the capture medium. The project aims to prove that the process is more energy-efficient and resource-saving than conventional processes, and that scalability to industrial plants is possible.

Project goal

Although there are already a number of mature processes for capturing CO2 from gas mixtures, they are still associated with very high running costs and high energy consumption in many application areas. For this reason, a great deal of research is still being done today to develop more efficient processes. One process that attracted some attention around the turn of the millennium is hydrate-based carbon capture (hbCC). In this process, CO2 is captured and stored in a molecular cage of water molecules-called the host network of CO2 hydrate (see figure).

To separate CO2 from a typically N2-rich gas mixture, the gas mixture and water must be brought into contact at high pressure and low temperature. While the CO2 molecules of the gas mixture are preferentially intercalated into the cages of the hydrate, the remaining gas components prefer to remain in the gas. With each incorporated CO2 molecule, the CO2 content in the gas decreases, gradually purifying it.

Conventional hydrate-based processes use water in liquid form, which limits process temperatures to a range above 0°C. Here, thermodynamic considerations clearly show that most performance factors would be better at lower deposition temperatures.

In the hbCC project, the FHV is choosing a seldom-trod synthesis route that bypasses the temperature limitation to positive Celsius and makes the advantages of deposition at low temperatures down to -50°C usable for the first time ever. The goal of the project is to demonstrate that these advantages can be realized in practice. In doing so, the FHV hopes to lay the foundation for further development and exploitation of the process.

Funding

This project is funded by the Climate and Energy Fund and carried out under the "Energy Research (e!MISSION)" program.

Facts

| project name | hbCC - Hydrate-based carbon capture using pressurized vapor deposition |

| Program | Energy Research (e!MISSION) |

| Project duration | 01.12.2021 - 28.02.2023 |

| Project budget ges. | 188,935.00 EUR |

| Share FHV | 151,148.00 EUR |